The system of IML consist of Injection molding machine, mould, mechanical hand, standard paper, raw materials, auxiliary equipment, etc,all related equipment can form an effective system and the compatibility is the key to the successful operation of the system.

In general, the composition of mould labeling equipment will clear a few sites: project evaluation period, initial investment cost, injection molding machine, mold, the IML, manipulator and all these technology need work together.The whole production system involves the modules of each unit, and the after-sales service of each module is of particular importance.

FIG.1

FIG.2

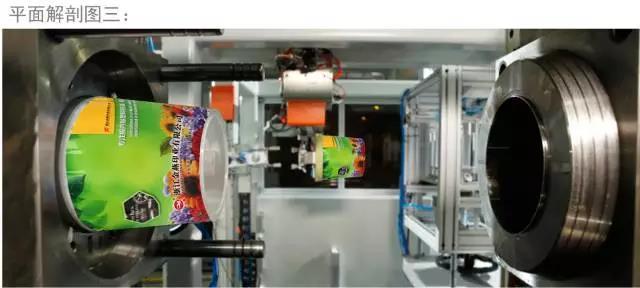

FIG.3

FIG.4

FIG.5

FIG.6

Our company,ZHEJIANG JINYAN PRINTING CO.,LTD. ,based on continuous R&D and manufacturing capabilities,we have proven technique on IML.We have the ability to develop and produce all kinds of product projects independently, and have professional design service and production capacity.The research on the structure of different products, as well as the guidance of early development and selection of materials, tailor-made for customers

The whole system of the IML is stable,high yield.The production can reduce the footprint of the product,and the capacity can be doubled at the same time,which help to save energy consumption and personnel cost, lower cost increases price competitiveness.